GUANGKEX

Dedicated to the development of precision electronic testing technology

SINCE

Precise testing, lean manufacturing

Make every product outstanding through precise testing

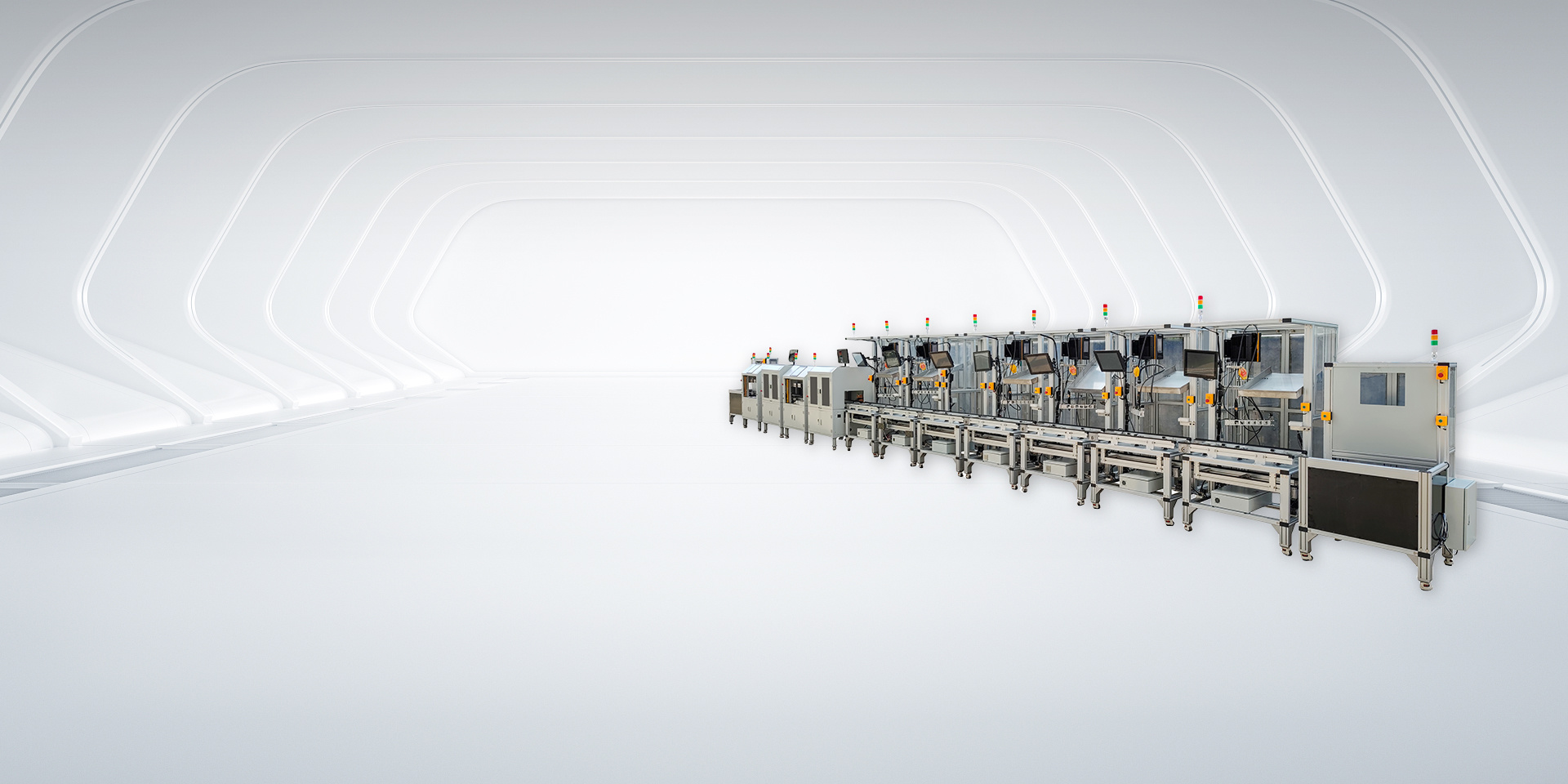

Suzhou Guangkex Electronic Technology Co., Ltd. was established in 2013. It is a high-tech enterprise dedicated to the development of precision electronic testing technology and providing customers with high-quality testing solutions. The company's business focuses on intelligent testing, automated assembly and testing integrated lines, non-standard automation, test fixtures, etc.

Products and Solutions

The company's business focuses on intelligent testing, automated assembly and testing lines, non-standard automation, test fixtures,etc.

After years of hard work, we have gained recognition from a large number of customers.

Serving the global manufacturing electronics industry chain!

Learn More ➜Application

Products are widely used in high-growth fields such as automotive electronics, consumer electronics, new energy vehicles, semiconductors, and medical.

News

Pay attention to Guangkex company information and learn about the dynamics of the electronic technology industry in real time

Analysis of the key points of PCBA test fixture production that can effectively improve productivity

PCBA testing is an extremely important part of the entire electronic manufacturing services. It can strictly control the quality of shipments in the final stage, find problems in time to adjust the previous processes such as SMT and DIP, optimize the process flow, and use a detection chain to control quality layer by layer. A good PCBA test fixture can make the entire PCBA processing process more efficient. Next, Shenzhen Honglijie will explain to you what key points you need to pay attention to for a good PCBA test fixture.

PDU automated assembly line device industry application that leads the industry trend

Intelligent PDU can also significantly reduce labor costs and improve operating efficiency. At present, many data centers are operated unattended. Once the equipment goes down, the business will be unable to operate for a long time, causing serious losses. One of the standard configurations of intelligent PDU equipment is the remote power management function. By configuring the corresponding remote power management software, operation and maintenance personnel can use the local area network or wide area network to detect, control and manage the power supply of multiple devices in computer rooms and cabinets distributed in various places, thereby saving labor costs.

Overview of the PCBA automatic test system with rave reviews

For different circuit board architectures, there are targeted PCBA automatic test systems, which are composed of various expansion units (such as instruments, power supplies, external sensors, communication modules) and user needs. The test system can efficiently complete various functional tests of circuit boards. The test system can use test software platforms such as labview, VB, C++, GPIB acquisition cards, DAQ test cards and external instruments, etc. The test software is general test software.

Popularize the basic standards and precautions for testing flexible circuit boards

FPC: Flexible circuit board (flexible PCB): referred to as "flexible board", also known as "flexible circuit board", also known as "flexible circuit board, flexible circuit board" or "flexible circuit board, flexible circuit board", widely used in many products such as mobile phones, laptops, PDAs, digital cameras, LCMs, etc. Generally divided into flexible circuit boards (flexible printed boards, commonly known as soft boards) and rigid-flexible printed boards (also known as soft-rigid boards).

Get Product Solutions

If you are interested in our products and services, please contact us or leave us a message, and we will be happy to serve you!